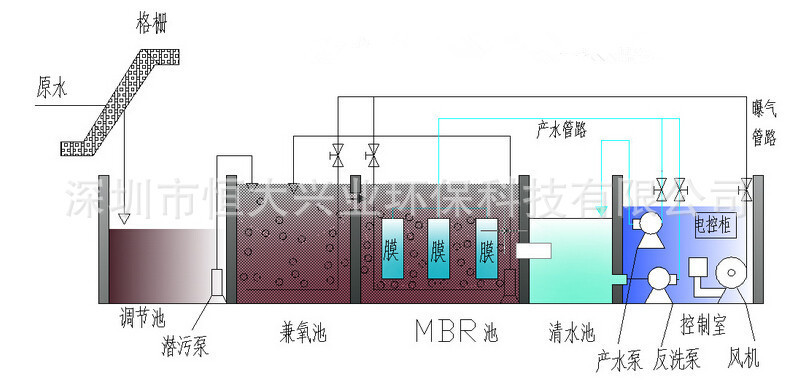

Rural integrated MBR sewage treatment

Product features of integrated MBR sewage treatment equipment:

1. The two-stage biological contact oxidation treatment process adopts plug-flow biological contact oxidation, and its treatment effect is better than that of a complete mixed type or two-stage series complete mixed type biological contact oxidation tank. It has a smaller volume than an activated sludge tank, strong adaptability to water quality, good impact load resistance, stable effluent water quality, and no sludge expansion. The new type of elastic three-dimensional packing is used in the pool, which has a large specific surface area, and is easy for microorganisms to hang on and remove the film. Under the same organic matter load condition, the removal rate of organic matter is high, and the solubility of oxygen in the air in water can be improved.

2. The biochemical tank adopts the biological contact oxidation method, the volume load of its filler is relatively low, the microorganisms are in their own oxidation stage, and the mud output is small.

3. The entire equipment processing system is equipped with a fully automatic electrical control system and equipment failure alarm system, which is safe and reliable in operation. Usually, there is no need for special personnel to manage, and only need to maintain and maintain the equipment in a timely manner.

How to use integrated MBR sewage treatment equipment:

1. Able to treat comprehensive wastewater from domestic systems and similar organic wastewater;

2. It adopts glass fiber reinforced plastic, carbon steel anti-corrosion, stainless steel structure, has excellent characteristics such as corrosion resistance and anti-aging, and has a service life of more than 50 years;

3. The complete set of devices is simple to construct and easy to operate. All mechanical equipment is automatically controlled, and all devices can be set below the surface.

Scope of application of integrated MBR sewage treatment equipment:

1. Hotels, restaurants, nursing homes, hospitals;

2. Residential districts, villages, and market towns;

3. Stations, airports, seaports, ships;

4. Factories, mines, troops, tourist spots, scenic spots;

5. Various industrial organic wastewater similar to domestic sewage.

Installation and maintenance of integrated MBR sewage treatment equipment:

1. Foundation: If the integrated domestic sewage treatment equipment is placed above the floor, you only need to prepare a concrete floor with the same shape as the equipment as the foundation. The foundation pressure must be greater than 4T/m2, and it is also required to be level and level.

If the equipment is buried below the floor, the elevation of the foundation must be less than or equal to the elevation of the equipment and ensure that there is no accumulation of water when it rains. The foundation is generally plain concrete (whether reinforcement depends on the local geological conditions).

2. Installation: According to the installation drawing, each box should be in place one by one. The position and direction of the box should not be misplaced, the distance between each other must be accurate, and the pipeline should be connected.

Pour clean water into the equipment and check whether the pipelines are leaking. If there is no leakage, cover soil around the box until the equipment inspection hole, and level the ground. Connect the control line of the electric control box to the water pump, and the electric control box to the power supply. When wiring, pay attention to the direction of the fan and the motor, which must be in the same direction as the fan.

![[nav:name]](/en/static/upload/image/20210731/1627700070576564.jpg)